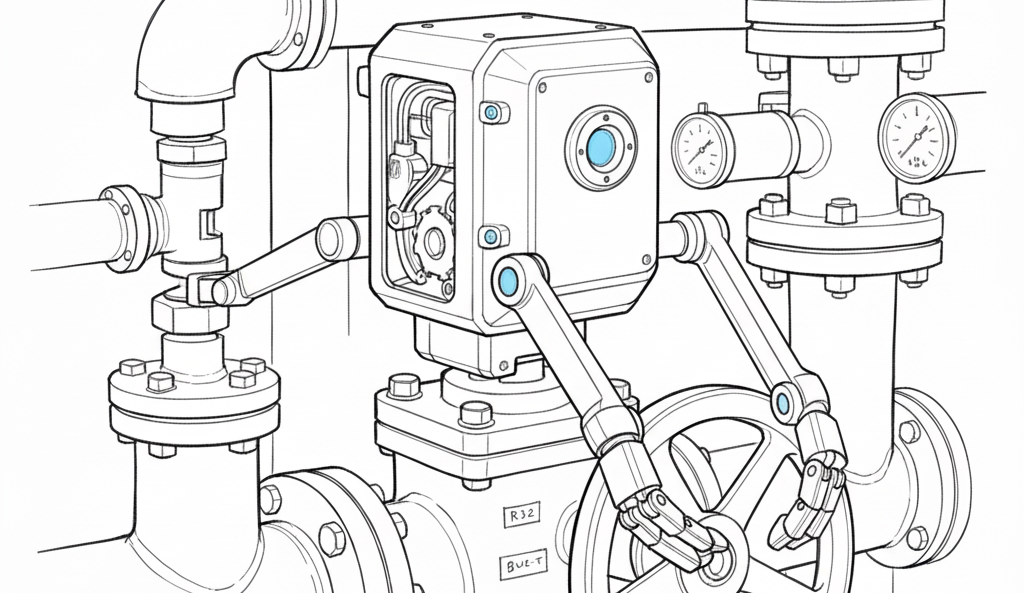

Most industrial sites have valves, dials, and knobs that would benefit from automation — but bespoke retrofit projects cost too much. We're building a simple, low-cost actuator that clips on and connects.

Think R2-D2's simpler little brother — affordable, focused on one job: turning things.

We're looking for partners to build the first prototype with.

Industrial sites have many manual controls that could benefit from automation. Adding a little smartness would go a long way. But bespoke automation projects are too expensive for most cases.

Valves, knobs, and dials that require physical adjustments — often in inconvenient or remote locations.

Custom automation or full equipment replacement doesn't make economic sense for each control point.

Small improvements to many controls could add up to significant operational gains — if automation was affordable.

What if we could add just enough intelligence — without the big project? That's the gap we're trying to fill.

Standard, proven components assembled in a practical way. We're using stepper motors, ESP32 controllers, 5G connectivity, and cloud IoT platforms.

Clamps or mounts to existing valves, knobs, or dials. Provides precise, repeatable motion.

Local control logic, position feedback, safety limits. Runs deterministic control loops.

WiFi, 5G, or LoRa depending on site infrastructure. Secure communication to cloud backend.

Remote control, data logging, and integration with existing SCADA or building management systems.

Adjust controls from anywhere without sending someone on-site. Could reduce response times and travel costs.

Collect position data and operational metrics from controls that were previously invisible to your systems.

Start with a few critical controls. If it works, expand. No need for all-or-nothing projects.

Fine-tune operations that couldn't justify automation before. Small gains at many points could add up.

We've built stepper motor systems, embedded controls, IoT connectivity, and cloud platforms. We have experience making things work in industrial environments, but we need real-world feedback to refine the approach.

Based in Finland. Focused on Nordic conditions.

We're at the concept validation stage. We believe this technical approach could work, but we need to build the first prototype WITH an operator who has real manual controls to automate.

This is co-development, not sales. We want to understand:

Help us figure out what to build and where to try it first. 30-minute technical discussion — no strings attached.

If you have manual controls that might benefit from this approach — or if you just think it's an interesting technical problem — let's talk.